From the very beginning, traffic light circuits have been used in the model books of the fischertechnik technical construction material to clarify functional electronic principles. These engineering models presented over time continue to capture the imagination. Once I had created the microcontroller-controlled traffic light control system, I decided to survey the historically preceding methods as well. This exploration taught me a lot about the various switching solutions. Therefore, I have devoted this page entirely to some possible manual switching solutions using the LED traffic lights already discussed in the previous section.

The cycle in which the colored lights alternate or burn at the same time varies from country to country. In the Netherlands, two bulbs of a tri-color traffic light never burn at the same time. The red light jumps immediately to green.

In other countries, for example in Germany, Hungary, Great Britain, Austria, Switzerland, Poland, Lithuania, Norway, Russia and Sweden, the yellow lamp announces the green light in the last part of the red phase. In the table to the right, this sequence is indicated at 'A'. Control cycle 'B' represents the Dutch situation. The difference is in phases 2 and 4 where only one lamp per traffic light is on.

The height of the table cells indicates the relative time that the corresponding lights are on. This is because the red and green phases are usually (much) longer than the phase in which the yellow lights are on.

The basis is a manual sequential switching of the three lights of a traffic light with a rotary switch (31312). With the rotary switch and an additional pushbutton, an “enhanced traffic light circuit” can be made where the yellow light joins the red, in accordance with the “German control cycle,” before the green light comes on.

To illustrate this principle, I built a manually operated traffic light circuit with the rotary switch and push button, as suggested in the booklet of the em2 (30231) construction kit. This involves placing a “handle” or pointer of building blocks on top of the rotary switch. Here is the original picture from the fischertechnik construction booklet.

This involves placing a “handle” or pointer of building blocks on top of the rotary switch. In the original description, it is left to the ingenuity of the builder himself to make the through connection between two opposing contacts on top of the rotary switch. Although it is suggested that these run in line with the indicator bar, there is no room to insert the fischertechnik plugs into the contacts on the inside.

I solved this by interconnecting two contacts with a soldered wire under the proposed handle construction. The simpler, but less elegant, solution is to move all the connectors on the bottom ring one contact position so that the through connection can be made on the outside with the normal plugs (the blue plugs in the picture above). All this led to the simplest, electromechanical, traffic light control with a manual rotary switch. Note that here we are controlling only one traffic light, for one direction of traffic.

Eventually, a more elegant method of making the through connection on top of the rotary switch also presented itself. After all, it is most pleasant if it can be realized in line with the rotary handle. That the contacts on the rotary switch are a non-fischertechnik size (about 33.5 mm) apart could be solved with two metal intermediate connectors 31339 in building blocks 32064 as shown in the picture. On top, a wire bridge can then be made with the regular fischertechnik plugs.

In the construction booklet of the Hobby3 Elektromechnanik box (35803), instead of a switch, a relay is used for the extra phase in which the red and yellow are lit at the same time, but the principle is the same. The circuit diagram takes the three lamps, and not the different phases of the traffic control, as its starting point. The rotary switch can be rotated through four positions that allow traffic light control for only one traffic light 'I' (see the table). This illustrates the principle for one traffic light.

However, if we want to control two traffic lights (traffic directions) simultaneously, this method falls short because the light phases of the red light and the green light of a two traffic lights are not purely complementary. The red light is on during the yellow cycle while the green light of the other traffic light is off. Therefore, a single connection for these lights in the two different traffic lights is not sufficient. As a result, in addition to the extra switch for the second yellow/red step, at least a second (preferably mechanically coupled) rotary switch would be required. Thus, five independent lamp groups should be able to be switched.

For controlling multiple lamps, it makes more sense to take the (only four) different phases of traffic control as a starting point and use a logic function to determine (to “decode”) for each lamp whether it is lit or extinguished in the respective phase. With this substantially different approach, we move more into the realm of (digital) switching electronics.

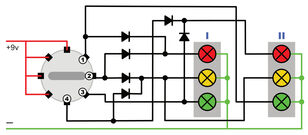

The desired switching logic for each lamp can be “decoded” even without electronics modules with logic ports. By adding only a few diodes to the wiring of the original circuit diagram, it is already possible to extend the control for two traffic lights and/or traffic directions. Below the modified circuit diagram is shown. A few 1N4001 or 1N4007 diodes are used to create the logical so-called “wired-ORs”. As a result, the four phases that can be passed through the rotary switch are sufficient and even the extra push button from the schematics above can be omitted. In this way, the rotary switch acts as the “counter” and the wiring with the diodes as the “decoder.

Thus, in this scheme, the four control cycle phases of the scheme were taken as a starting point. The four completed phases of the control are then logically “decoded” according to the “wired-OR” switching logic as constructed above with the diodes. This makes it possible to control two traffic lights with one rotary switch without an additional pushbutton.

These switching principles can of course be motorized and therefore “automated” by having a motor perform the turning movement, which here still has to be done by hand. A disadvantage of a rotary switch, however, remains the “dead” moments between switching positions. At these moments, of course, simply no lamp burns!

The yellow lamp joining the red one before the green light comes on was realized in the booklet (35803/39530) to the Hobby3 box with a relay instead of a push button next to the rotary switch. It was also already suggested to extend the simple traffic light switching with the rotary switch with a flashing yellow light switched by means of a motor with cam. Completely electromechanical solutions, however, these are not yet. After all, the fischertechnik rotary switch (31312) must be turned by hand each time.

The booklet of the em2 (30231) construction kit shows the example constructed here. These contacts of this arrangement are moved by cam disks. As a result, the successive contact phases are “programmed” with cam disks. The premise here is that these four phases follow each other as precisely as possible without overlap. In this case, this 'phase sequencer' or counter is similar to the manual rotary switch and the 'decoding' wiring with the diodes of Figure 7 could be used to control the two traffic lights. However, such a mechanical four-step 'counter' remains prone to error. If errors occur in the 'programming' due to mutual twisting of the cams, this irrevocably leads to errors in the control of the lights.

In this respect, a superstructure with trailing contacts 31301 with Schleifring-Unterbrecherstücke 31303 might be a better idea. This would at least make it easier to divide a rotation of the driven axle into four phases. Since two of the four phases can also be “coded” at the same slip contact each time, the risk of errors due to mutual distortion is reduced. In addition, only two slip contacts suffice, instead of four separate cams.

Immediately after building up the first traffic control system, manually operated with a rotary switch, it did become clear to me that it makes more sense to use the different phases in the control cycle as a starting point rather than the individual lights of the traffic lights.

A further improvement, however, would be if the four control cycle steps were thereby guaranteed to alternate seamlessly without undefined and undesirable intermediate moments or overlap. As long as we solve this mechanically or manually this will be difficult to guarantee. To this end, we will have to resort to electronics. The basic idea is that the four different control cycles are run electronically, allowing a split between the control phases and the eventually “decoded” lamp combinations. This is made possible by a counter that counts from 1 to 4 (or from 0 to 3) and a separate 'decoder' with logic gates. On the follow-up page of this project, I explore these possibilities.